JET GROUTING SOIL IMPROVEMENT

Schnabel, recognized as one of America’s premier design-build contractors, offers top-tier jet grouting soil improvement solutions to tackle a variety of operational challenges. Our innovative approach enables clients to meet their construction objectives with confidence.

Jet grouting is a powerful technique for enhancing soil stability, effectively reducing groundwater seepage into underground structures. It is also an ideal solution for underpinning existing buildings and providing excavation support.

As one of the nation’s leading jet grouting contractors, we specialize in creating cement-stabilized soil to control groundwater and provide robust foundation support.

With decades of expertise in the field, Schnabel is equipped to help you navigate complex jobsite conditions and successfully reach your project goals.

JET GROUTING SOLUTIONS

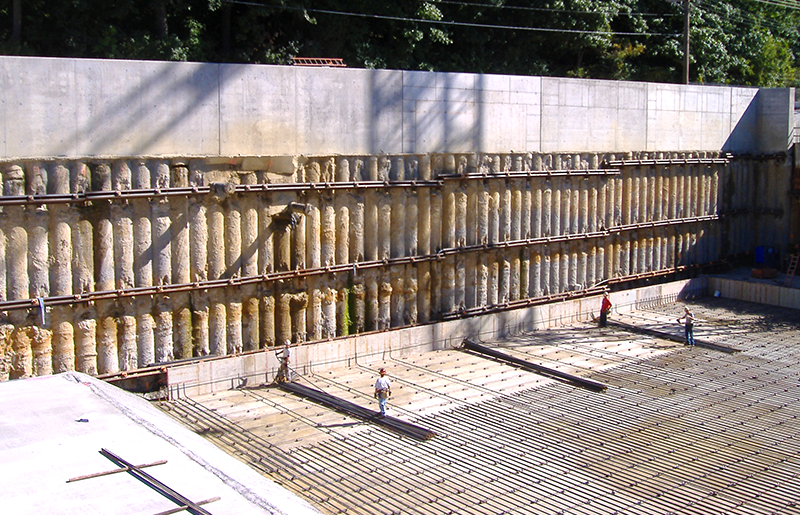

Jet grouting soil improvement is a specialized technique that involves mixing soil with an injected cement grout on-site to form a cement-stabilized soil column. With precise quality control, this method enhances the soil’s strength and reduces its permeability. As a result, the treated soil becomes a reliable engineered material for foundation support and groundwater management. Common uses for this method include underpinning existing structures and constructing cutoff walls to support excavations.

The process begins with the installation of a small-diameter pipe, typically 4 inches in diameter, which is drilled or jetted down to the desired treatment depth. Once at the correct depth, a neat cement grout is injected under high pressure—often up to 6,000 psi—through the ports at the bottom of the drill pipe. The pipe is then rotated and gradually withdrawn, creating a circular column of stabilized soil. By adjusting the withdrawal rate, contractors can control the size of the jet grouting columns, whether for vertical support or to form overlapping columns that create a barrier to the lateral movement of weak soils or groundwater.

Jet grouting soil improvement is particularly advantageous when treating areas with existing utilities or underground obstructions, as the small diameter of the injection pipe allows for precise placement of grout columns even in tight spaces. This flexibility makes jet grouting an ideal solution for complex or constrained sites.

A VITAL PARTNER FOR CLIENTS WITH CHALLENGING PROJECTS ACROSS THE UNITED STATES.

JET GROUTING CASE STUDIES

Lower Olentangy Tunnel Project | Columbus, OH

Granite Construction, the general contractor, hired Schnabel for jet grouting along the 3.2-mile tunnel. Grouting was planned at 4 tunnel shafts for TBM break-in and break-out, 12 Safe Haven sites for cutterhead replacement, and 5 locations where a water main crosses the TBM alignment. Despite project challenges, Schnabel completed the work ahead of schedule.

J Avenue Water Treatment Plant | Cedar Rapid, IA

Schnabel installed 67 jet grout columns to support the expansion of the J Avenue water treatment plant in Cedar Rapids, Iowa. This project required an excavation adjacent to an existing structure. The continuous wall of jet grout columns was successful in retaining the soil and water behind the wall and no measurable settlement of the tank structure occurred.

The Minneapolis Children’s Hospital project was Schnabel’s first application of jet grouting to underpin an existing structure in lieu of traditional hand-dug underpinning pits. The project team was very pleased with the performance of the jet grout underpinning system.