JET GROUTING

One of America’s top design-build contractors, Schnabel provides exceptional jet grouting solutions that help clients overcome unique operational challenges and achieve their construction goals.

Jet grouting is an effective way to reduce groundwater seepage into underground structures. It can also be used for underpinning existing structures and excavation support.

As one of America’s leading jet grouting contractors, we are specialists in creating cement-stabilized soil for groundwater control and foundation support.

With decades of experience, Schnabel has the expertise to help you overcome your jobsite challenges and achieve your operational goals.

JET GROUTING SOLUTIONS

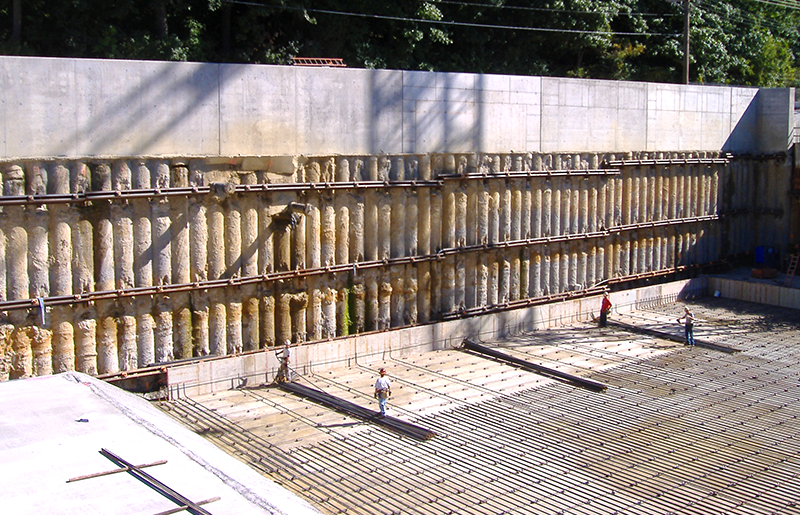

Jet grouting is a procedure for mixing soil with injected cement grout in-situ (on site) to create a cement-stabilized soil column. With proper quality control, the stabilized soil exhibits increased strength and decreased permeability. These modified properties allow the stabilized soil to be used as an engineered product for foundation support and groundwater control. Underpinning of existing structures and cutoff walls for excavation support are two typical applications.

Jet grouting involves the drilling or jetting of a small-diameter pipe, typically around 4 inches in diameter, to the bottom of the desired treatment depth. Once that depth is reached, contractors inject a neat cement grout under high pressure, typically around 6,000 psi, through ports at the bottom end of the drill pipe as the pipe is rotated and withdrawn to create a circular column of treated soil. The rate of withdrawal can be varied to increase or decrease the diameter of the jet grout columns. These columns are located as required for vertical support or overlapped to create a wall or barrier to the horizontal movement of weak soil and groundwater.

Jet grouting is particularly effective when the subsurface to be treated contains existing utilities or other buried obstructions, since the small-diameter pipe can fit between them and create a larger diameter column in the soil below.

AN INDISPENSABLE PARTNER FOR CLIENTS WITH COMPLEX PROJECTS THROUGHOUT THE UNITED STATES.

JET GROUTING CASE STUDIES

Lower Olentangy Tunnel Project | Columbus, OH

Granite Construction, the general contractor, hired Schnabel for jet grouting along the 3.2-mile tunnel. Grouting was planned at 4 tunnel shafts for TBM break-in and break-out, 12 Safe Haven sites for cutterhead replacement, and 5 locations where a water main crosses the TBM alignment. Despite project challenges, Schnabel completed the work ahead of schedule.

J Avenue Water Treatment Plant | Cedar Rapid, IA

Schnabel installed 67 jet grout columns to support the expansion of the J Avenue water treatment plant in Cedar Rapids, Iowa. This project required an excavation adjacent to an existing structure. The continuous wall of jet grout columns was successful in retaining the soil and water behind the wall and no measurable settlement of the tank structure occurred.

The Minneapolis Children’s Hospital project was Schnabel’s first application of jet grouting to underpin an existing structure in lieu of traditional hand-dug underpinning pits. The project team was very pleased with the performance of the jet grout underpinning system.